Philosophy

Astondoa is a Spanish company which is proud to be family operated for four generations and counting. With more than 100 years of shipbuilding experience, it continues to lead the yachting industry. The company was founded on the principles of professionalism, reliability, and quality. Yet, the company is not stuck in the past. It looks toward the future with firm commitment to technological development, design, and innovation.

Everything must meet the highest quality standards. That’s why we perform every task at our shipyard. All woodwork, mechanical, polyester and upholstery processes are carried out by our skilled staff.

At Astilleros Astondoa, constructing a yacht requires passion and creativity. Every vessel is designed around the preferences of each new owner. They are unique and custom-made with acute attention to detail. No two Astondoa yachts are alike.

Throughout its extensive history, the company has chosen to focus on building customized yachts rather than mass production. Aiming to satisfy an exclusive number of clients gives meaning to our work. Clients who choose Astondoa have exceptional perception of value, individuality, and quality.

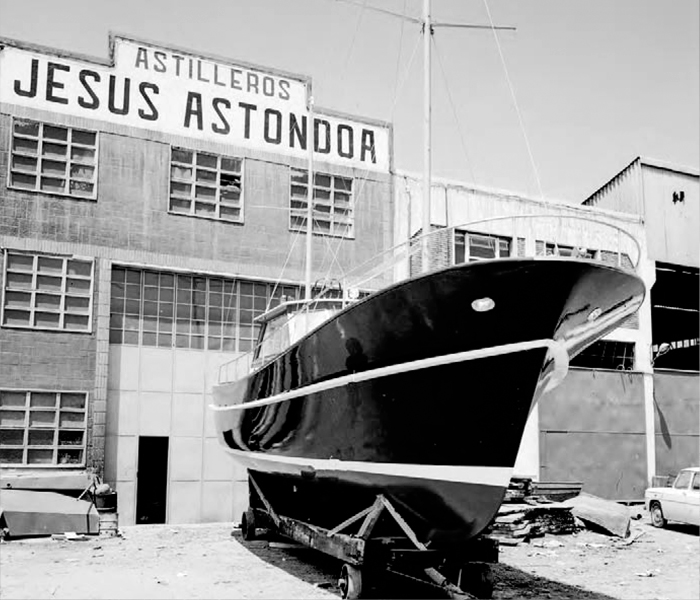

ASTONDOA’S history dates back to 1916, when the brothers – Jesús and José Astondoa Martínez – started building rowboats and traineras in a small carpenter’s workshop in Portugalete, Spain. Activity was put on hold during the Spanish Civil War. Then, after that, they decided to go in different directions. Jesús Astondoa focused on building fishing and recreational boats. In 1944, his son Jesús Astondoa Santamaría joined the family business and took over the shipyard shortly thereafter. Astondoa’s well-made wooden boats and high-quality finishes helped the shipyard to gain national recognition. The foundation for success had been laid.

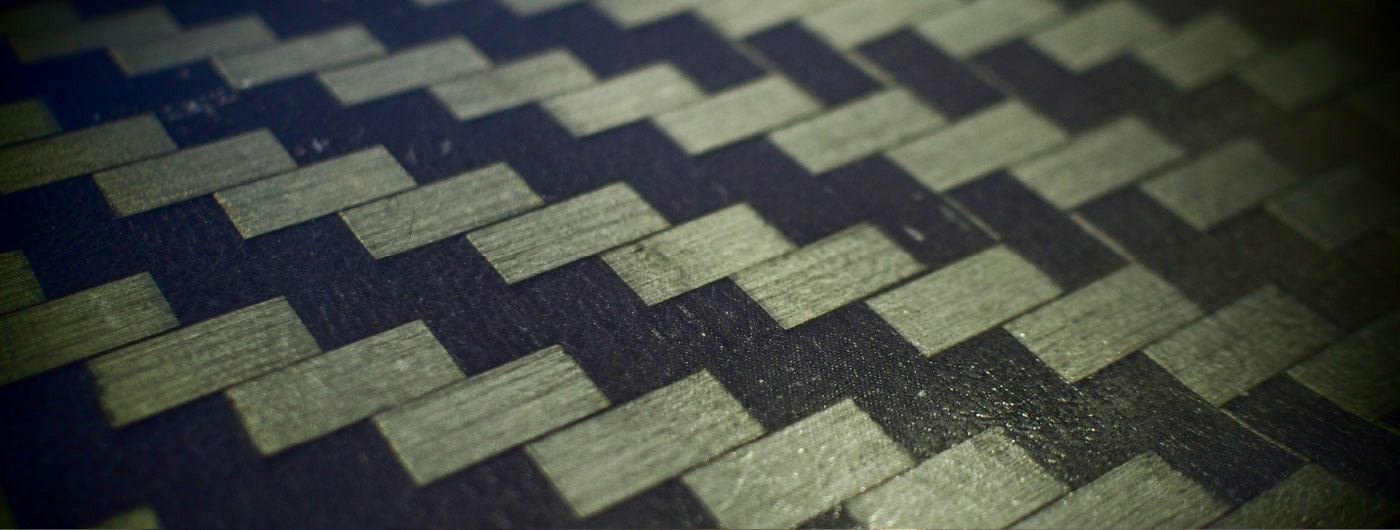

Once the company had established itself on Spain’s east coast as well, the children of Jesús Astondoa Santamaría, the family’s third generation, also joined the shipyard. In the early 1980s, Astondoa stepped away from its traditional wood production methods and began building boats in polyester resin reinforced with fiberglass.

Advances in production techniques, combined with stylish design, strengthened Astondoa’s position as a leading European shipyard. Participation at international boat shows and award recognition for superior quality, fueled a period of development that continues to this day.

By 2006, the Astondoa Group had more than 500 employees and boasted the most extensive range of boats on the market manufactured by a single brand. Its fleet includes 40 ft open boats, yachts over 120 ft long made of polyester resin reinforced with fiberglass, and megayachts up to 45m long with steel hulls and aluminum superstructures.

Throughout the company’s proud 100-year history, Astilleros Astondoa has crafted more than 3,000 vessels. Today, the Astondoa family remains at the helms of the shipyard. They have overcome a century’s worth of challenges thanks to their firm belief in hard work. To date, four generations of Astondoa yacht builders have upheld the tradition of professionalism, reliability and quality.

Astilleros Astondoa sits on the seafront of Santa Pola, Spain. Located just a 10-minute drive from Alicante’s international airport, the shipyard spans over 323,000 sq. ft (30,000 sq. mt.) and focuses on building yachts longer than 122 ft. The entire design phase and production process take place inside the shipyard.

Astondoa has an extraordinary workforce that builds every boat according to the needs of the owner. Individual prototypes are made with the latest CAD-CAM technology. Using a 5-axis milling machine, the largest utilized for boat construction in the country, we make detailed 1:1 models at our facility. Then, these models are transformed into moulds to build the vessels.

In all, Astilleros Astondoa has four industrial facilities that manufacture all the ship parts separately using advanced techniques, such as vacuum infusion. In the carpentry division, our expert craftsmen transform natural teak trunks into gorgeous sheets of wood used for flooring and to make all types of furniture for yacht interiors. Our mechanical department shapes metals, including iron, bronze, and steel using electronic equipment. The skilled lathe operators and welders are able to create, adjust and position every part according to the technical specifications of each vessel. Upholsterers work with the finest leathers to make gorgeous, comfortable furnishings. These different departments work symbiotically and with a constant focus on the owner’s expectations.

Our employees represent our most important asset. Every Astondoa yacht passes through the hands of more than 150 experts who pour their effort and knowledge into each component. This makes every vessel a unique jewel. The Astilleros Astondoa shipyard has a large careening area for stowing ships, a 15-tonne crane for handling smaller boats, and a travel lift for launching ships that weigh up to 150 tonnes. There is a painting facility for boats up to 40 meters long, and special structures are built to paint larger vessels. These facilities are used to manufacture new vessels and carry out maintenance and refit projects for existing ones.

The management and administration units are also located in Santa Pola. Two additional facilities are strategically located on the peninsula. The team in Gador is dedicating to building Faeton yachts ranching from 23 to 36ft in length. The shipyard facility in Almansa manufactures Astondoa models under 52ft. The Classic division is also located in Almansa, where it meticulously builds all the unique, handcrafted furniture for our yachts.

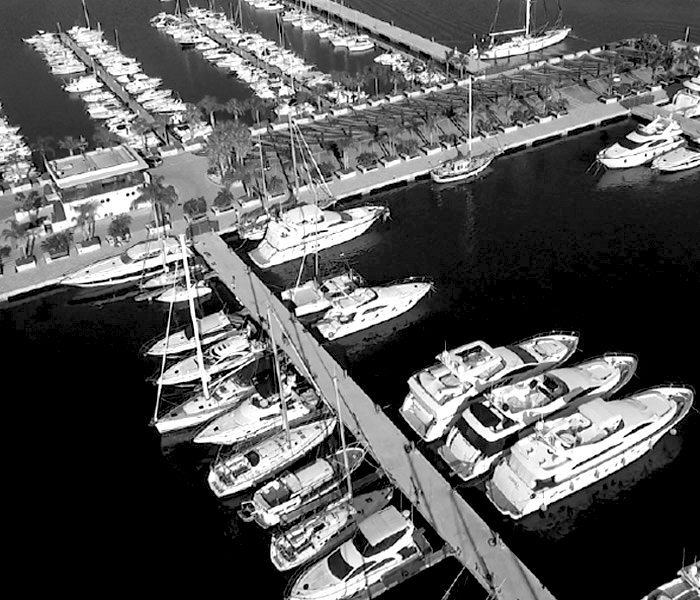

The Astondoa Group’s facilities include Marina Astondoa, which is located next to our shipyard. Yacht owners love the convenience of berthing at a state-of-the-art port center when having yacht services carried out. The marina facility has 40 berths available for Astondoa owners and yachts requiring technical support.

Astondoa is aware of the shortage of berths in the yachting industry, which is why it has created Marina Miramar. This company aims to build and operate new, high-quality marinas.

The company’s first project is called Marina Miramar, a nautical sports complex for mooring ships up to 50-meters long. It has a total of 260 berths as well as restaurants, cafes, parking, and retail space. It has quickly become a renown nautical infrastructure in Spain.

Astondoa’s specialized technology hub, which leads the study and design of new vessel concepts, is located in Santa Pola, on Spain’s Mediterranean coast. Utilizing thorough analysis and development, designers create new models with the support of our engineering team. Every boat, shape and detail undergoes hundreds of hours of analysis to draft the best lines for each model.

Astondoa is an active member of national technology centers which provide comprehensive solutions, innovative research and development projects, technology services, competitive intelligence, and training.

The shipyard uses high-tech equipment such as advanced 3D printers. It also owns Spain’s largest five-axis machining center specialized in shipbuilding. All the models and moulds used to manufacture Astondoa boats are made here.

Astondoa was one of the first European manufacturers to implement an infusion-based mass construction system that ensures homogeneous and precise resin application. The process is executed in a vacuum for perfectly distributed the resin, resulting in optimized space, flexibility and weight.

Our research has made it possible to create lighter hulls that are more resistant than conventional materials, resulting in lower fuel consumption and faster boats. Lighter weight hulls are achieved without sacrificing resistance or durability. Additionally, we work to ensure that production processes do not release contaminants into the environment.

A focus on environmental conservation has led Astondoa Group’s partnership with the Miguel Hernandez University in Elche, Spain. Together, we are working on a number research projects about the environmental impact of recreational boating and shipbuilding processes. Our commitment to the environment is also seen in the company’s involvement with the Tabarca Limpia project aimed at cleaning the local water and seabed.

At Astondoa, we focus all our efforts on guaranteeing the high quality of our boats and providing optimal after-sales service. Our exclusive Astondoa Service program begins before a boat is even delivered to her new owner. Each ship undergoes rigorous control tests in which every technical specification is verified and analyzed according to protocol by shipyard technicians.

All Astondoa vessels are approved by the main international certifying agencies, including RINA and Germanischer Lloyd.

Our yachts come with an exclusive regular maintenance program. Maintenance services and revisions can be carried out at the owner’s connivence by any Astondoa facility, authorized distributor, or service provider.

With the Astondoa International Care program, our company can provide additional services anywhere in the world. This is an added value of the warranty offered through the support of an extensive sales and technical service network that covers five continents.

Additionally, Astondoa offers a full range of refit services built around customers requirements and expectations. Our ships are known for their long-lasting durability and excellent condition, year after year. Astondoa designs are considered timeless classics and, as needs change, we can refit any boat to meet the requests of individual owners. Our skilled team modifies, repairs, renovates and updates parts, equipment, and furniture to older yachts to meet the owner’s specifications and preferences. Aside from Astondoa owners, many owners with yachts by other brands take advantage of this service.